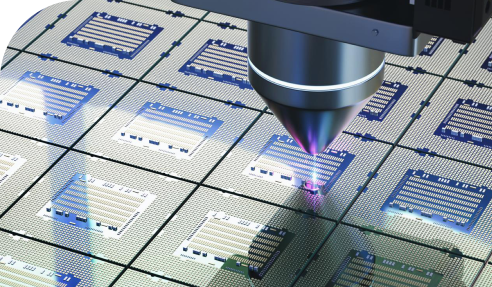

Mainly detect the circuit board gold finger dirt, foreign objects, deformation, scratches, finger peeling deformation, scratches, overflowing glue less glue, dirty and so on.

Mainly detects component surface skewing, foreign object attachment, foreign colour, missing parts, part deformation, rubber missing, scratches, bumps, part shift, tin overflow, residual foreign objects, indentation, scratches, cracks, polarity reversal a

Mainly detects defects such as stains, bumps, scratches, pits, burrs and other defects in the appearance of irregular parts.

Mainly detect the appearance of steel shell bumps, oxidation, dents, scratches, indentation, deformation, welding slag, dirty, bulging, bursting point, two-dimensional code, characters, dents, corrosion, electrolyte contamination, abrasion, yellowing and

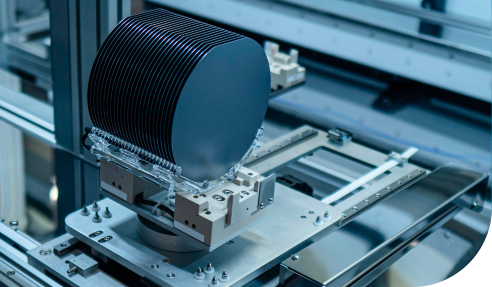

The company has been committed to technological innovation and continuously launches industry-leading equipment products to meet customers' demands for high-quality and high-efficiency equipment.

The company has years of experience in equipment manufacturing and can provide professional customized equipment solutions based on customers' specific needs, meeting their personalized needs and helping them achieve production goals.

The company strictly controls product quality, adhering to high standards and strict requirements in every aspect from raw material procurement to production and manufacturing, ensuring that customer technical requirements are met and equipment can operat

The company has established a comprehensive after-sales service system, including equipment installation and commissioning, technical training, regular maintenance, and a fast response fault handling mechanism, allowing customers to have no worries during